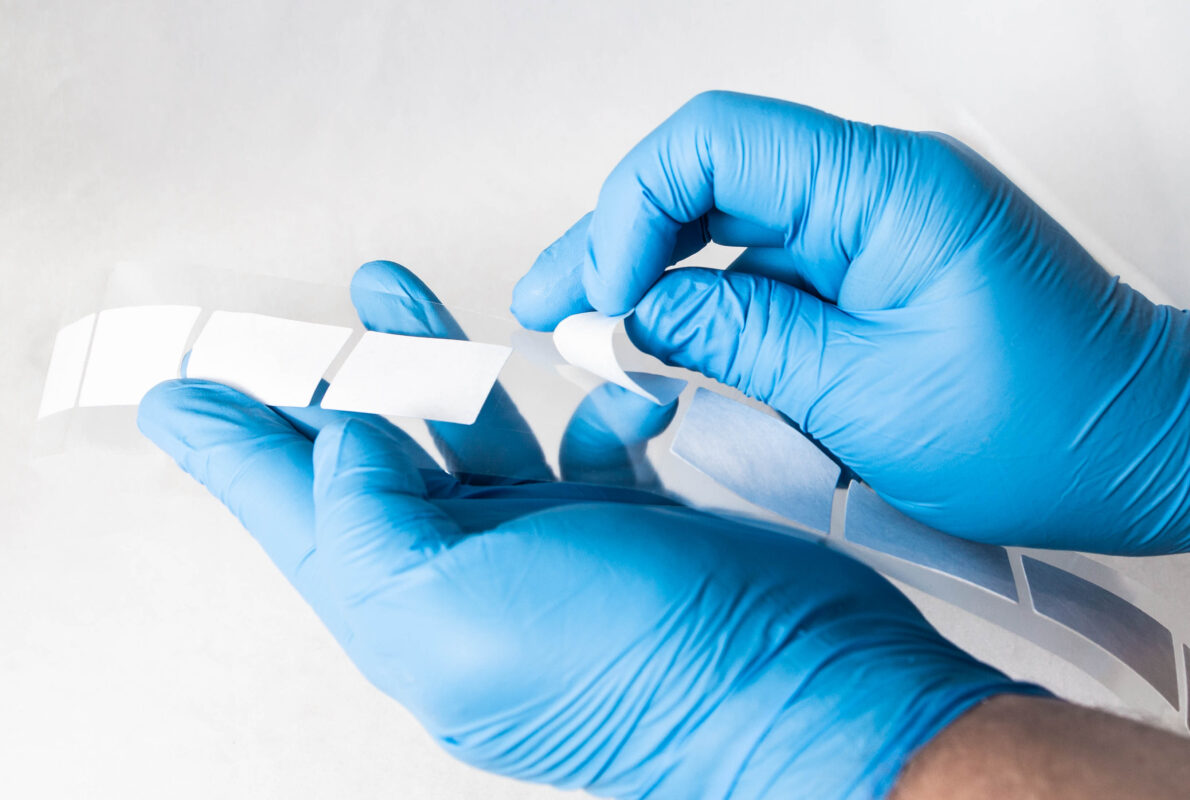

We have all used sticky notes or two-sided tapes, but do you know what are those called? Absolutely right! Release liners! This is nothing but a plastic film sheet that prevents the sticky surface from adhering prematurely. The plastic-based film is coated with a release agent whose job is to provide a release effect to any adhesive or mastic material. With such an interesting function, let us stick to the world of the release liners market and learn about its materials, growth factors, applications, and technologies used.

Adhesive Market and Growing Demand

The release liners market in total was valued at USD 92.44 billion in 2023 and is expected to grow at a CAGR of 7.3%, generating revenue of USD 162.4 billion by 2032. This market is fuelled by significant development in printing technologies. Other factors that fuel the market are:

- The use of release liners in the food & beverage industry is on the rise due to their benefits, including ready-to-eat options, quick cooking, and convenience, contributing to market growth.

- The increasing global population and demand for packaging items are driving the demand for release liners, as labels and tapes are also in high demand.

- Factors such as rapid urbanization, rising disposable income, and the growing demand for packaged food and beverage products further increase demand for release liners.

- Growing demand for industrial labels is driving the expansion of the release liners market, as they play a crucial role in the packaging industry and product supply chain.

Substrates And Their Properties

Liner materials, known as substrates, are used to make these release liners. These substrate options offer a range of properties, enabling release liners to cater to diverse industry needs. The choice of substrate depends on specific application requirements such as adhesion, printability, durability, and environmental factors. There are 2 types of liners as follows:

1. Paper-Based Release Liner

- Glassine/Calendered Kraft Paper: Glassine or calendered kraft paper is a popular substrate choice for release liners. It offers smoothness, transparency, and excellent release properties, making it suitable for applications like labels, tapes, and graphic arts.

- Polyolefin Coated Paper: Polyolefin coated paper provides enhanced moisture resistance and improved dimensional stability. It is commonly used in industries requiring high-performance release liners, such as medical and automotive applications.

- Clay-Coated Paper: Clay-coated paper offers a high-quality surface finish and superior printability. It is often utilized in pressure-sensitive label applications where precise graphics and text are essential.

- Others: Other paper-based substrates, such as supercalendered or silicone-coated paper, may also be used for specific release liner requirements. These substrates offer varying levels of smoothness, strength, and release characteristics.

The paper-based release liners are expected to drive the release liners market growth and will be responsible for the largest market share.

2. Film-Based Release Liner

- Polyvinyl Chloride (PVC): PVC film-based release liners provide excellent dimensional stability and resistance to temperature extremes. They are commonly used in applications requiring durability and long-term adhesion, such as automotive and industrial labels.

- Polypropylene: Polypropylene film-based release liners are known for their high tensile strength and chemical resistance. They are often used in applications where moisture resistance and tear resistance are important, such as tapes and medical products.

- Polyethylene: Polyethylene film-based release liners offer good flexibility and conformability. They are widely used in applications like food packaging, pressure-sensitive labels, and general-purpose adhesive products.

- Others: Some other film-based release liners are Polyethylene Terephthalate (PET), Polystyrene, etc. PET film-based release liners provide excellent mechanical properties, such as high tensile strength and dimensional stability. In contrast, Polystyrene is lightweight and offers good die-cutting capabilities.

To Tape It All Together

The release liners have a wide range of applications, such as in Labels, Pressure-sensitive tapes, Hygiene, Industrial, Graphic Arts, Medical, etc. North America is already acing the market due to the development in its healthcare industry. Looking at this pace of the release liners market, It will flourish and stick to its growth and expand hugely during the forecast period.