Inspection machines involve mechanical, manual, and computerized techniques which inspect products, packages, and packaging elements to sanction they comply to stipulations. Market augmentation will be helped by makers’ viewpoint on automation so that it satiates conveying consumer demands about product attributes because of speedy industrialization. The inspection machines market size is expanding to provide aggregate benefits such as lesser prices, enhanced preciseness, and a curtailment in errors which assists producers in improvising profits while preserving the finest products.

The size of the inspection machines market was estimated at USD 845.21 million in 2022, and it is anticipated to develop at a compound annual growth rate (CAGR) of 5.5% with a revenue forecast of USD 1437.59 million.

The Functionality of Inspection Machines

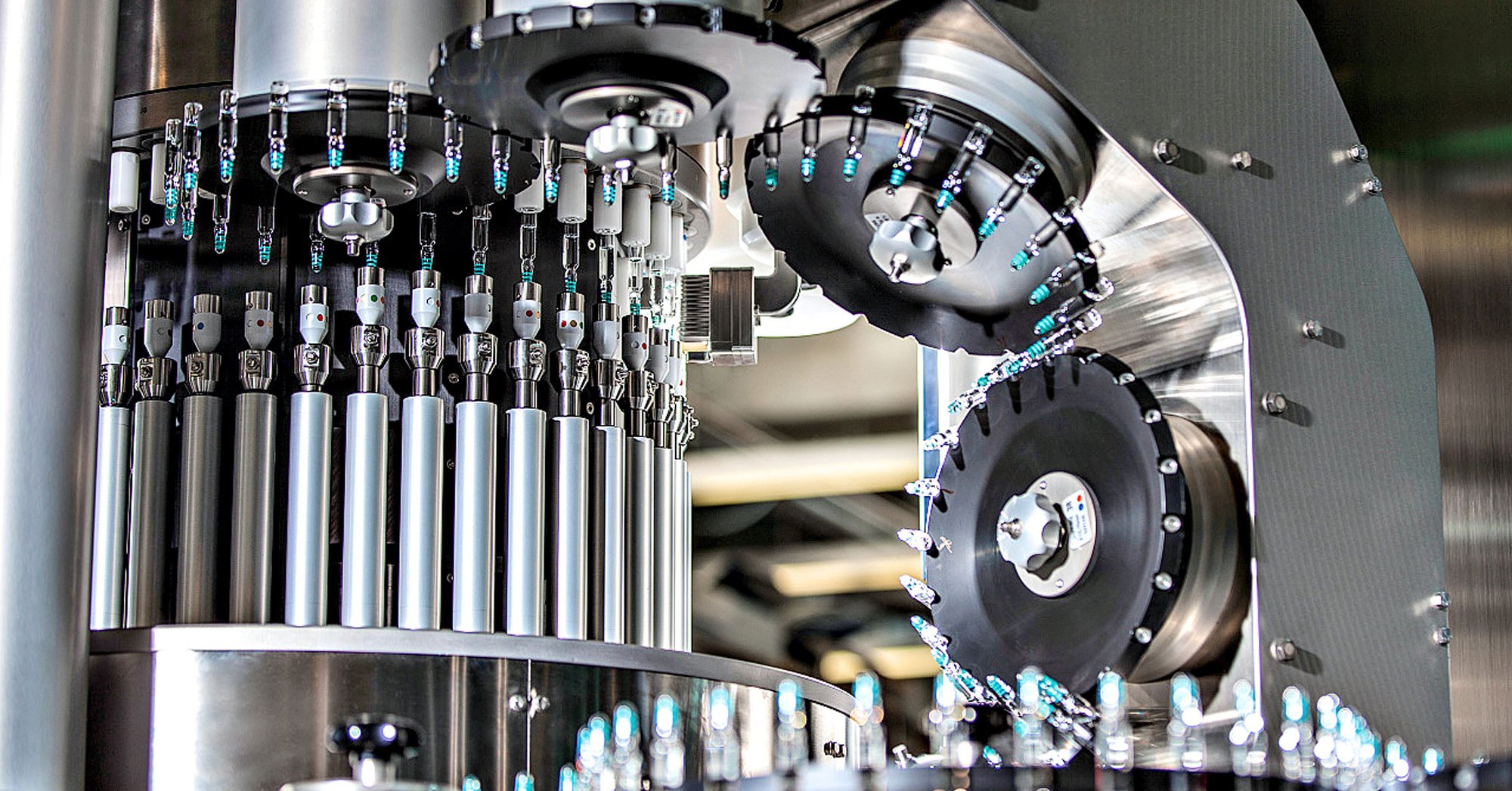

Inspection machines utilize a gamut of technologies and arrangements to examine whether or not commodities encounter needed statements within provided forbearance and discovering any pollutants or faults. Based on the product and industry inspection incorporates size, color, mass, the existence of distant bodies in a product or package, pack coherence, misplaced labels or commodities, or inaccurate data on labels, products, or packaging.

What Are the Types of Inspection Equipment?

The most usual configuration of inspection machines is color sorters, checkweighers, and metal detectors, but the scope of inspection equipment obtainable has developed hugely lately. The escalating usage of automatic and semi-automatic structures is propelled by the requirement to make production more methodical and to discard the requirement for staff who execute manual chores as well as inspecting commodities and packs vividly.

Progression in technology has also enhanced the gamut of inspection chores that can be executed. For instance, conversely, traditional metal detectors were restricted to locating ferrous metal, which is magnetic and conductive. Varied technologies indicate that it is now probable to locate glass, bone, fiber, wood, and most nonferrous metals as well. Improvised vision systems do not permit detailed or correct inspection of pill and blister packs and affirmation of foodstuff.

Growth Drivers

Designers and engineers can categorize syringes, blister packs, catheters, and tablets and carry out swift scrutiny with the assistance of inspection machines. These gadgets involve systems for oxygen detection, metal detection, pressure inspection, and leak detection.

Inspection machine market sales are soaring as local governments and makers are both diligently witnessing new solutions to the issue of consistently escalating medicine and vaccination demand. Many biopharmaceutical firms, academic institutions, contract research organizations, and contract development and manufacturing firms are mechanizing their laboratory processes to obtain escalated accuracy and swift reversal to terminate the demand-supply gap.

Geographic Reach

North America: The augmentation can be credited to proliferating demand from pharmaceutical and cosmetic companies. The government has embraced an advanced inspection system due to critical product quality standards. The utilization of machine vision technology is becoming a quality implementation in the food and beverage sector and is helping producers in enhancing ingenuity, product standard, and labor security.

Asia Pacific: The demand for surface vision and inspection systems is being propelled by the speedy industrialization of advancing countries, the prevalence of notable semiconductors, electronics, and automotive makers, and the setting up of standard directives.

Key Players

Some of the major players operating in the global inspection machines market include Baumer Inspection, Adept Technology, Inc, Cognex Corporation, Edmund Optics Inc, ETS SuperVision BV, Industrial Vision Systems Ltd, Microscan Systems Inc, Matrox Imaging, etc.

Recent Developments

In January 2022, Ishida launched an X-ray inspection system for enhanced sensitivity. The Ishida IX-G2-F incorporates a new line sensor that provides a high-quality X-ray image through an enhanced signal-to-noise ratio.

To Conclude

It has been observed that a rising aggregate of inspection endpoints is prevalent throughout the production line. In the inspection machines market, this will boost the sales of inspection machines. Albeit, amalgamating inspection equipment in the manufacturing and packing line is onerous due to the intricacy of machines and the escalated end-use domain. On the contrary, growing funding in biotech and pharma research and developmental activities is expected to initiate lucrative opportunities for the market.